Exception: Create Pick Cart

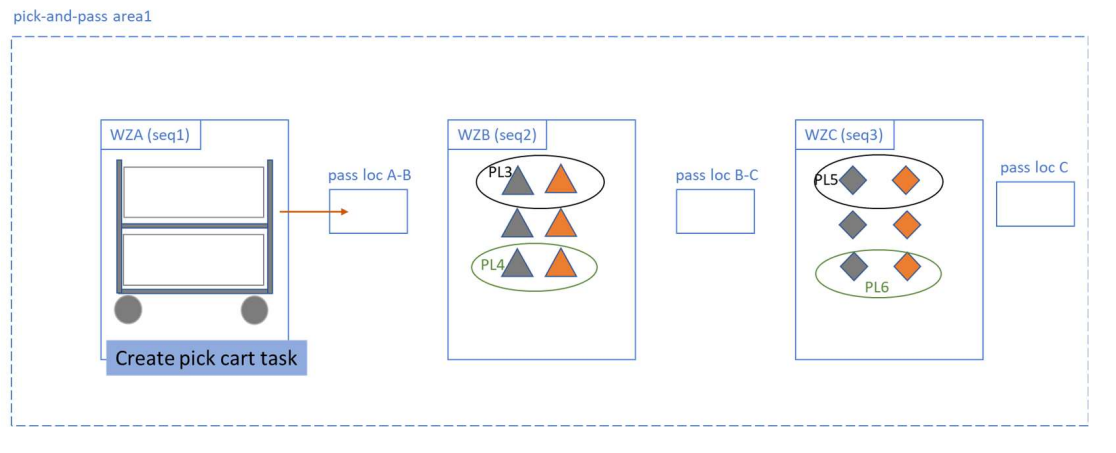

In this flow, for Order 1 and Order 2, the inventory is located exclusively in work zones B and C, with no inventory in work zone A. To accommodate this scenario, the picking process involves an additional task of creating an empty pick cart for work zone A, which is then sent to the designated drop-off location. The main inventory picking process occurs in work zones B and C and follows the typical multi-order pick list creation for each of these zones.

When the empty pick cart reaches work zone B, the inventory for both Order 1 and Order 2 is picked from work zone B and then passed to the next work zone C via drop-off location, and the process continues until all the items for both orders are picked.