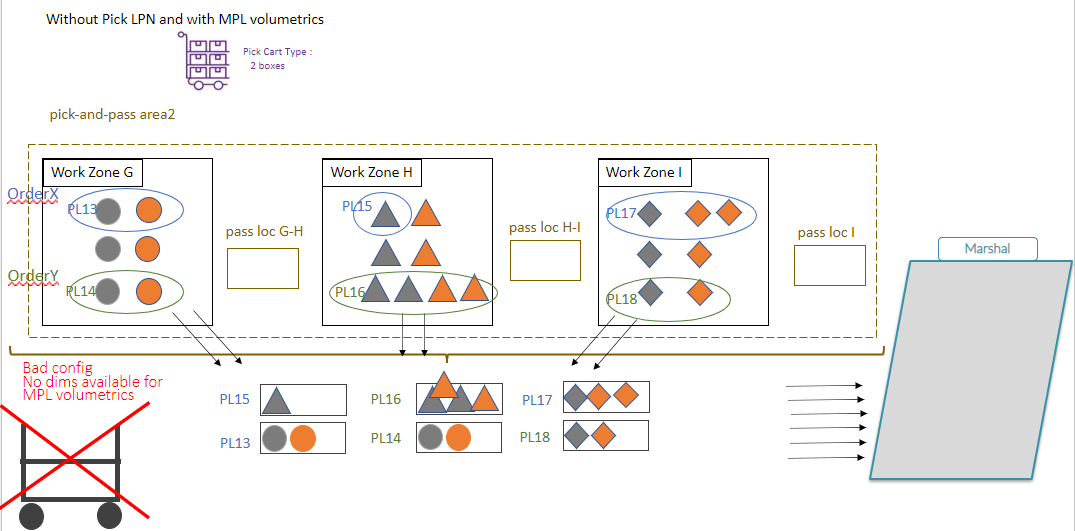

Flow 3: Multi-pick list in a pick & pass zone with volumetrics calculation with separate LPN per work zone.

This flow follows the same picking method as described in Flow 1: Multi-pick list in a pick & pass zone with a separate LPN per work zone but differs in volumetric calculation. The external volumetrics system calculates carton volumetrics and multi-pick list volumetrics in two steps.

Based on the possible available pick containers, items, and quantities of items required per order, the external volumetric system calculates carton volumetrics and provides information about how many containers are required and how many items it can carry. Based on the received information, the pick list can be split where applicable. In this example, the container type is box, and it can carry a maximum of three items.

For Order 1, three containers are required, and there are three PL. Container PL-1 can carry two inventories from work zone A; container PL-3 can carry one inventory from work zone B; and container PL-5 can carry three inventories from work zone C.

Similarly, for Order 2, four containers are required, and there are four PL. Container PL-2 can carry two inventories from work zone A; since work zone B has four inventories to be picked, two containers are required, and hence the PL in work zone B will be split into PL-4 and PL-4b. Container PL-4 can carry three inventories, container PL-4b can carry one inventory, and container PL-6 can carry two inventories from work zone C.

Note: The container used for one PL in a work zone is not used for any other PL in the next work zone.

In the next step, the external volumetric system calculates multi-pick list volumetrics based on the available pick carts, the number and type of containers that need to be carried per order and provides information about the type of pick carts and the number and position of containers on the pick cart. In this example, the pick cart can carry two containers. The containers of the same order will be grouped in the pick cart.

For Order 1, container PL-1 from work zone A and container PL-3 from work zone B will be placed in one pick cart called Pick Cart 001, and container PL5 from work zone C will be placed in Pick Cart 004. For Order 2, container PL-2 from work zone A and container PL-4 from work zone B will be placed in a Pick Cart 002, and container PL-4b from work zone B and container PL-6 from work zone C will be placed in a Pick Cart 003. Overall, in this flow for two orders, four pick carts are required, and each pick cart carries a container of the same order.

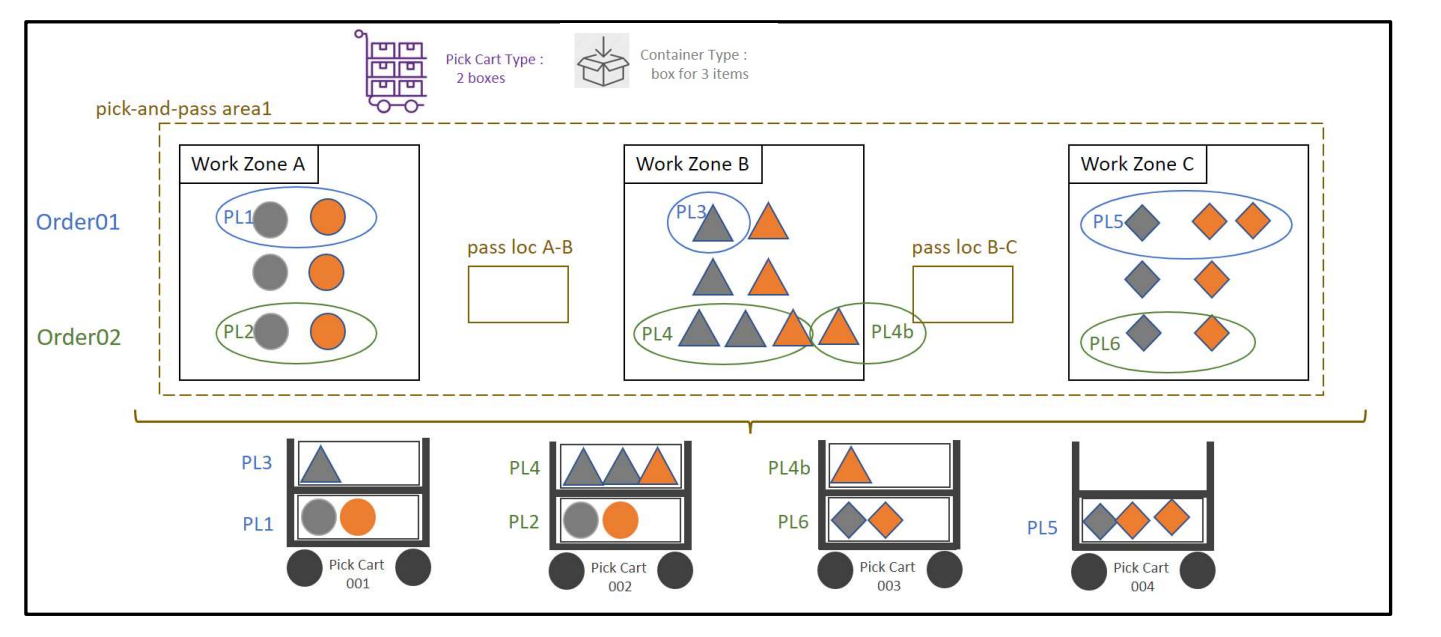

Example for bad configuration: Without Pick LPN and with MPL volumetrics.

In a similar scenario, where only MPL volumetrics are enabled and Pick LPN volumetrics are disabled, problems may arise. The external volumetric system lacks the necessary information about the dimensions and quantity of cartons, which leads to the failure of the MPL volumetric calculation. As a result, such a configuration cannot be supported.