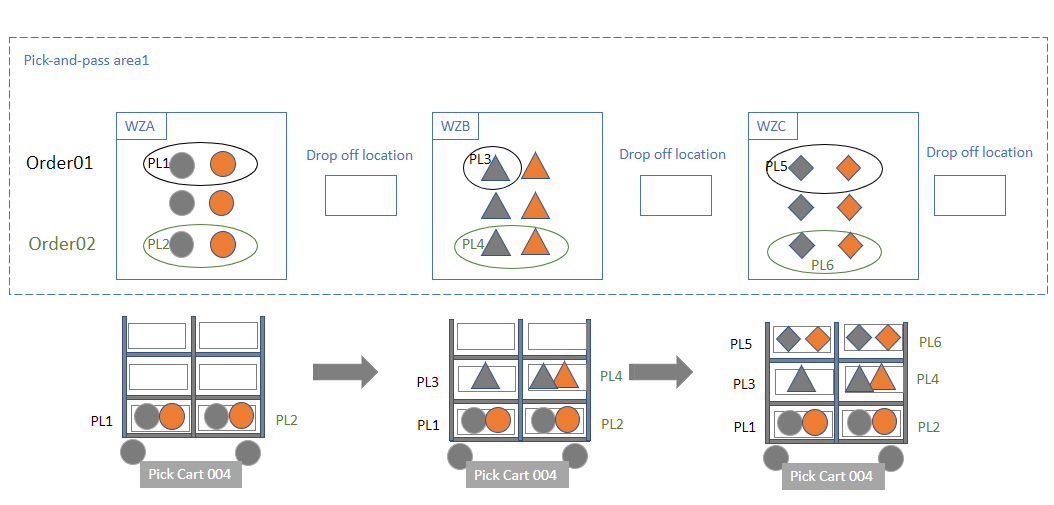

Pick and Pass Zone

Pick and pass refers to a picking technique employed in a warehouse that has been divided into distinct zones, with individual pickers assigned to each zone. In this approach, pickers are responsible for picking up all the items from a customer's order that are stored within their designated zone. Once they have completed their pick, the pick cart containing these items is then placed in a drop-off location. This drop-off location serves as an intermediate point where the cart is transferred to the next zone. In the next zone, newly assigned pickers repeat the process. This sequence continues until all the items required for the order have been collected.

Example:

For Order 1 and Order 2, if the inventory is in three different work zones: A, B, and C, one or more multi-order pick list can be created for each work zone. The inventory for both Order 1 and Order 2 is picked from each work zone and then passed to the next zone via drop off location until all the items for both orders are picked.

| Order | Zone A | Zone B | Zone C |

|---|---|---|---|

| Order 1 | Item |

Item |

Item |

| Order 2 | Item |

Item |

Item |

Picking process:

- Pick Item

for Order 1.

for Order 1. - Pick Item

for Order 2.

for Order 2. - Pass the picked items to the next Zone B via drop off location.

- Pick Item

for Order 1.

for Order 1. - Pick Item

for Order 2.

for Order 2. - Pass the picked items to the next Zone C via drop of location.

- Pick Item

for Order 1.

for Order 1. - Pick Item

Order 2.

Order 2. - Complete the picking process for both Order 1 and Order 2.

|