Optional operation

Optional operations are those operations that can be executed as an alternative route to a standard production route in an unforeseen situation. Under normal circumstances, we don't require these operations.

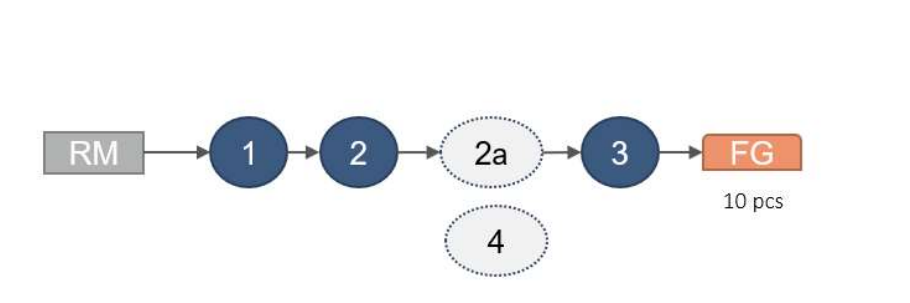

For example, the production of a finished good (FG) has a default route that includes operations 1, 2, and 3 in a sequential order. If operation 2 develops a defect during production, optional operations 2a (linked) or 4 (unlinked) can be activated as an alternative route. When operation 2 becomes functional again, you can switch from the optional operation to the default operation.

|