Alternative operation

Alternative operations are those operations that temporarily provide an alternative route for a standard production route in an unforeseen situation.

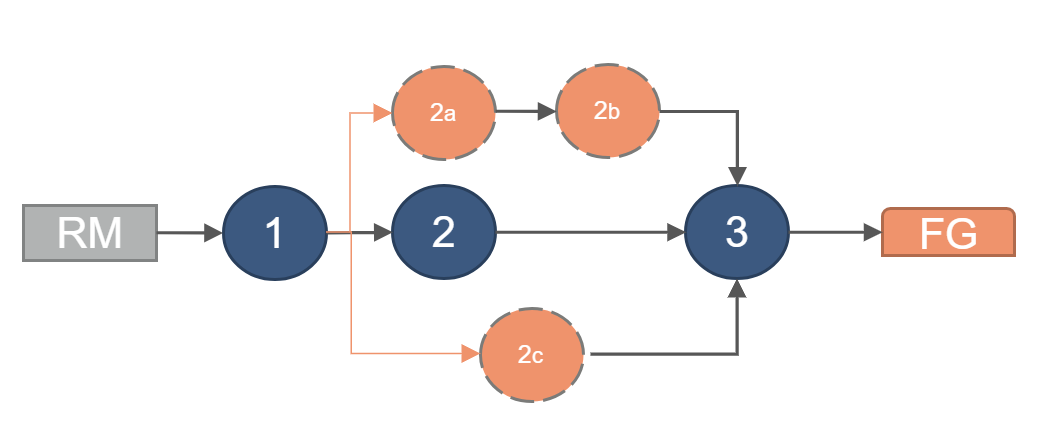

For example, the production of a finished good (FG) has a default route that includes operations 1, 2, and 3 in a sequential order. If Operation 2 develops a defect during production, you can activate an alternative route, replacing operation 2 by a single operation 2c or by a set of operations 2a and 2b in a sequence. When operation 2 becomes functional again, you can switch from the alternative operation to the default operation.

| A default operation is a standardized manufacturing process which includes a predefined template for specific operations, that contain details like machine, resources, labor requirements, and quality standards. These are commonly used ways to produce a particular product. |