Inventory Locks

Inventory can be locked so that no items can be picked or added.

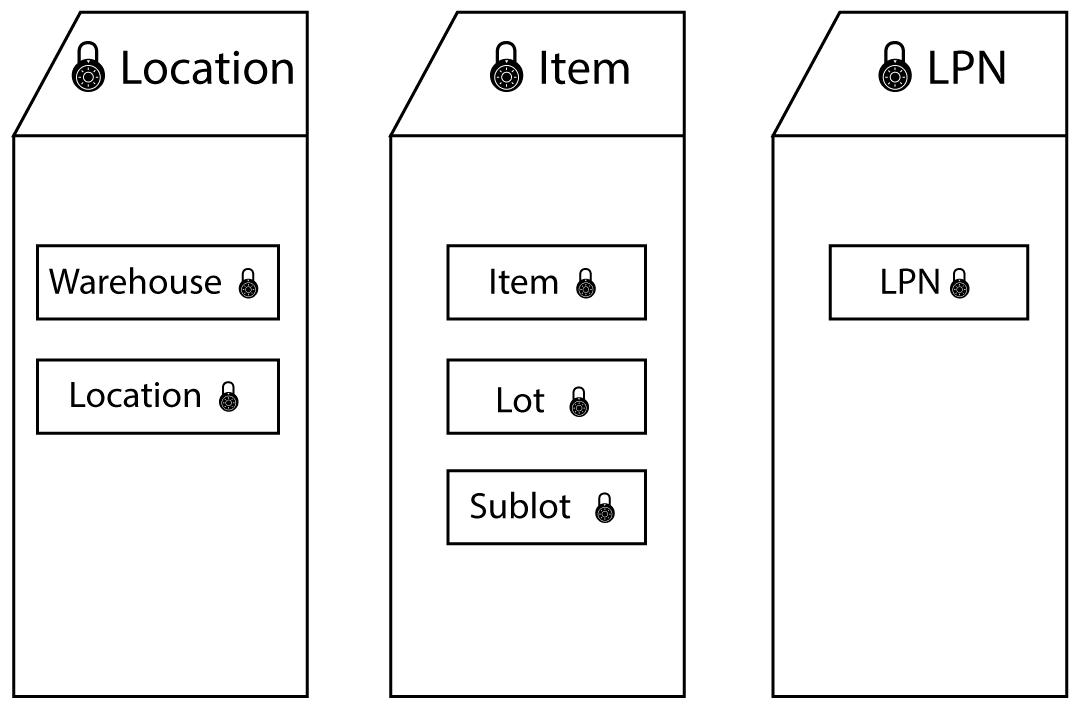

The inventory can be locked at three levels.

-

location lock: Warehouse or Location (aisle, rack, shelf, bin)

For example: When a stock count is in progress at a certain location.

It is also possible to lock storage zones, mobile racks (module Automated Storage and Retrieval Systems (ASRS)) and pick zones (module Advanced Picking Management). -

item lock (independent of the location where the item is positioned)

For example: Item A is locked because it does not meet safety standards

-

lot or sublot

For example: A lot is past the expiration date and must be destroyed

-

LPN lock

For example: An LPN is locked because the items it contains are damaged by water

An inventory lock can be placed on one or more locations (at your discretion) or on a storage zone (inventory lock for all locations of the selected storage zone). The lock status can be changed via a computer or the inventory lock function of the RF device (if authorized).

| There is no default interface regarding inventory levels for goods on logistically blocked locations and/or LPNs. We presume that this functionality is used for temporary logistic problems (for clearing an aisle for maintenance, for example), and that these actions do not have an immediate impact on the available inventory levels! |