WMS Rules

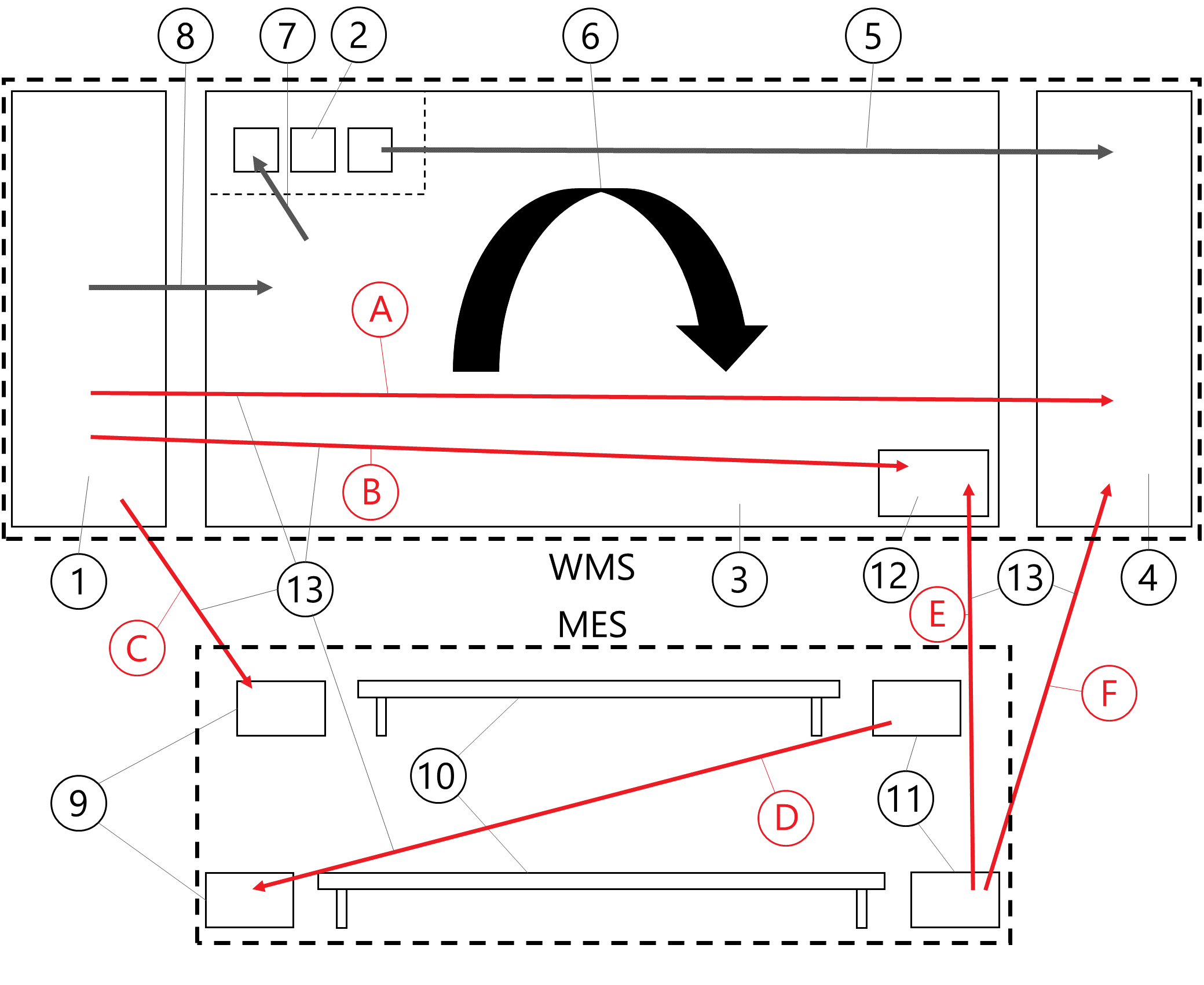

Several rules and scenarios can be created to manage logistic activities:

- Putaway (8): after receipt of goods (from third parties or from production) the putaway rules determine the suitable storage locations and their preferences for the item

- Relocation (6): in the case of an internal relocation of inventory that is already stored, relocation rules are used to set the suitable storage locations and their preference for the item

For example: a relocation rule can be added to an item for which the ABC classification has changed (from slow mover C to fast mover A) , ensuring that an item gets a location that is more easily accessible

- Picking (5): pick rules determine how and when the inventory of an item is allocated by the system

Example: a pick rule is added to an item with certain inventory attributes and a certain QC status so that this item is always picked in this way

- Replenishment (7): replenish rules record the allocation of inventory of an item for the replenishment of a pick location, pick zone or LPN buffer

Example: a replenish rule is added to an item at a pick location, ensuring that the item at the pick location is replenished from a certain storage zone in the warehouse

- Crossdocking (13): crossdock rules determine whether received/produced stock of an item can be reserved for crossdocking to an outstanding (backorder) requirement for production/outbound orders Examples:

- a crossdock rule is added to an item with certain inventory attributes and a certain QC status so that this item is always crossdocked in this way

- crossdock rules are added to items at an inbound location that ensure that the items can be crossdocked to a specific location

- The following movements are possible via crossdocking:

- (A) Inbound area to marshaling area

- (B) Inbound area to repack work center

- (C) Inbound area to WIP-IN

- (D) WIP-OUT to WIP-IN

- (E) WIP-OUT to repack work center

- (F) WIP-OUT to marshaling area

1. Inbound Area 6. Relocation 11. WIP-OUT 2. Pick Location 7. Replenishment 12. Repack work center 3. Warehouse 8. Putaway 13. Crossdock 4.. Marshaling Area 9. WIP-IN 5. Picking 10. Production line

These rules and scenarios are prepared according to the physical and logical organization of the warehouse, the common way of working and the various items.