Partial allocation of inputs

Partial allocations are appropriate for long running production orders that need large input quantities.

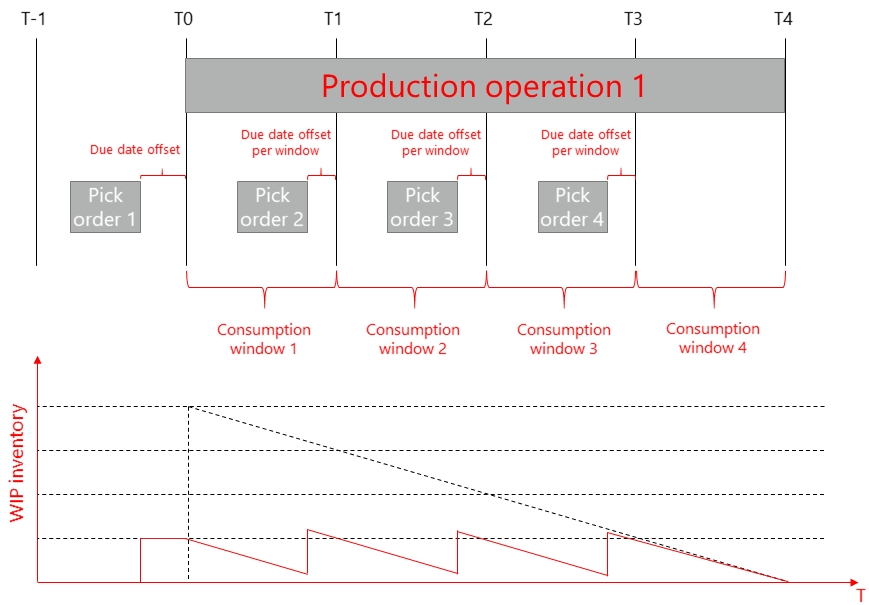

If all inputs for such an order have to be allocated in one go, these are not available anymore for other orders that are running at the same time, and a lack of space will often occur on the WIP-IN locations. To avoid this situation, it can be set that within one and the same production order the allocation of inputs is subdivided in a number of consumption windows (consumption periods), each with a separate allocation.

The due date offset is the time interval between the due date for the pickings and the planned start of the partial production. In the Configurator, a separate offset can be set for the first consumption window and the subsequent consumption windows.

The first pick order is generated when planning the operation. When this pick order is released (manually or by PLE), the next one is automatically generated to handle the next allocation/picking cycle, etc.

| For inputs which are disabled for a running production order via the Objective Operator Client, no more pick orders will be generated. |

The actual progress of the actual production window is monitored by PLE, and the due dates and target values will automatically be updated. Besides the actual production speed, several unexpected anomalies or events concerning inventory which is/was on its way to WIP-IN will also be considered (interrupts, inventory adjustments, unavailable or defective inventory,...). In case of shortages, PLE will release the following pick order earlier, so the production process is disrupted as little as possible.

The production process can be suspended by closing a pick order (via Close Pick Order

![]() ). The picking status of the operation is rendered in orange, which indicates that the automatic PLE flow is suspended. Restarting the PLE flow can be done via Allocate Shortages

). The picking status of the operation is rendered in orange, which indicates that the automatic PLE flow is suspended. Restarting the PLE flow can be done via Allocate Shortages

![]() , which will generate a new pick order.

, which will generate a new pick order.

It is recommended to configure a separate PLE flow for each input item for partial allocation.

If, when working with various inputs within 1 PLE flow, the ratio between these inputs appears not to be correct, the target values can be edited on the relevant pick line(s).