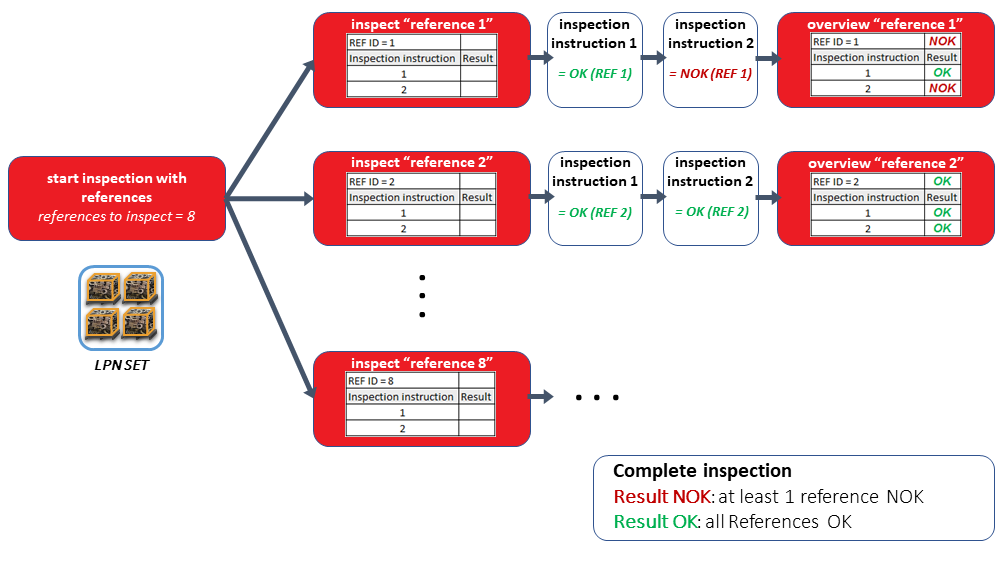

Inspections with references

Inspections with references are typically used in discrete environments.

| The default value for the Ref ID is an empty value. If required, a specific value can be entered during the inspection. |

Depending on the settings in the Configurator regarding the handling of an inspection instruction, one and the same inspection instruction can be processed one or more times, with one or more registrations per ref ID.

| The handling of an inspection instruction can be configured using Configurator . |

- Single Execution

Only one result is recorded for each inspection instruction. The result cannot be overwritten again. A Ref ID is not needed but can be entered as info.

- Allow Multiple Results

The last result entered for each Ref ID is recorded for the inspection instruction. This result is thus overwritten if the inspection instruction is re-processed for the same Ref ID.

All the registrations can be viewed under the tab Events. - Multiple Results Per Reference

All results entered are registered for the inspection instruction. A Ref ID is possible, but not necessary. This method is suitable for inspections of items that do not have to be uniquely identified. The number of registered results for each inspection instruction gives a representation of the number of items that were inspected.

| Single Execution | Allow Multiple Results | Multiple Results Per Reference | ||||

| e.g. flour for bread | e.g. gear | e.g. a box of nuts (100 in a box, 3 samples) | ||||

| Ref ID | Value | Ref ID | Value | Ref ID | Value | |

| Inspection Instruction 1 | OK | 125 | OK | box1 | 12.01 mm | |

| 126 | NOK | box1 | 11.98 mm | |||

| 127 | OK | box1 | 12.00 mm | |||

| Inspection Instruction 2 | 10 | 125 | 421 | box1 | OK | |

| 126 | 423 | box1 | NOK | |||

| 127 | 419 | box1 | OK | |||