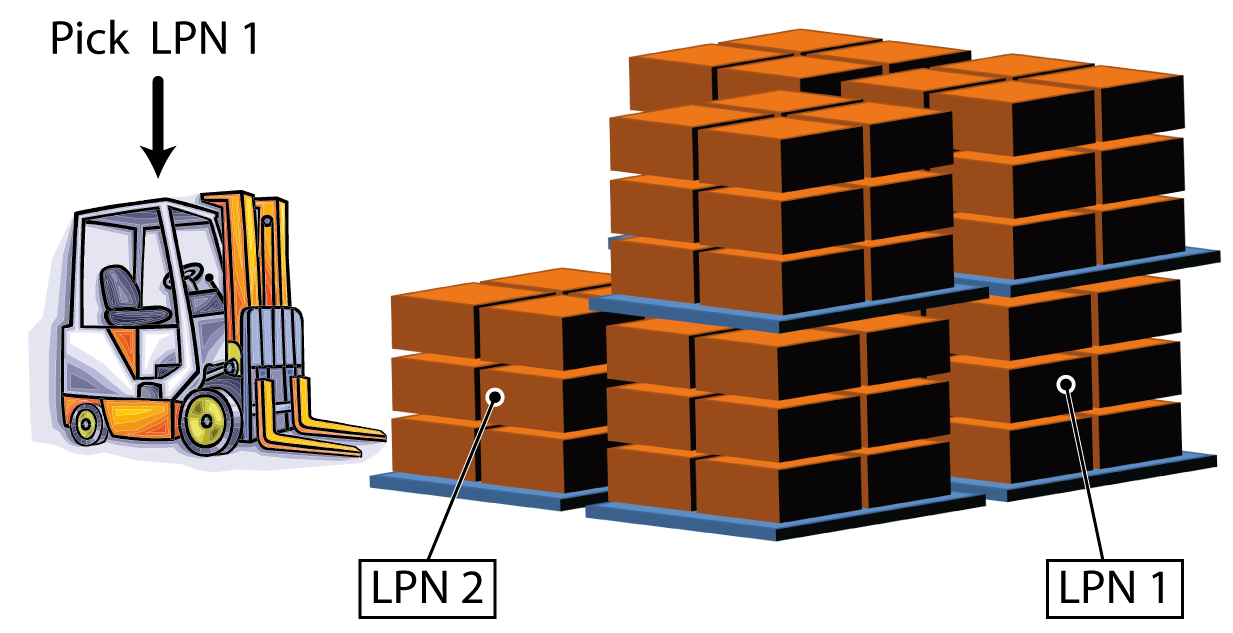

LPN swap

At a drive-in or floor location type (painted lines on the floor where multiple carriers can stand next to/behind each other or stacked on top of each other) it is recommended to enable an LPN swap. The forklift driver gets the instruction task to collect LPN1 on the location and to put it away. LPN1, however, is not directly reachable. If an LPN swap is enabled on this location, the forklift driver can use and putaway an equivalent carrier LPN2.

The LPN can also be changed when relocating mixed LPNs and Top LPNs. The LPN does not have to be identical to the presented LPN. The request on the order must be complied with and an allocation rule (Pick / Replenish) must be configured that validates this new LPN. It is possible to swap with an LPN with a different quantity provided that:

- the Search for LPN rule is configured with the option Round allocation to full LPN checked (the system can allocate more than requested).

- when a swap is made with an LPN that has less inventory, the order does not have a shortage. The quantity must be at least the same as the requested quantity according to the order.

Example: 10 units of item A are requested for an order. The Search for LPN rule is configured with the option Round allocation to full LPN checked and an LPN with 15 units of item A is allocated.

- The operator wants to swap with an LPN with 15 units of item A: OK, because the same quantity as the allocated LPN.

- The operator wants to swap with an LPN with 20 units of item A: OK, because the option Round allocation to full LPN is checked and so more can be allocated than requested.

- The operator wants to swap with an LPN with 5 units of item A: NOT OK, because this would mean a shortage for the order.